The rough skins are pickled or chilled when they are supplied at the tannery. Well conserved skins are a determining factor for the quality of the final product.

The skins are soaked and treated with a depilatory. Rests of meat or fat or other unusable parts are moved.

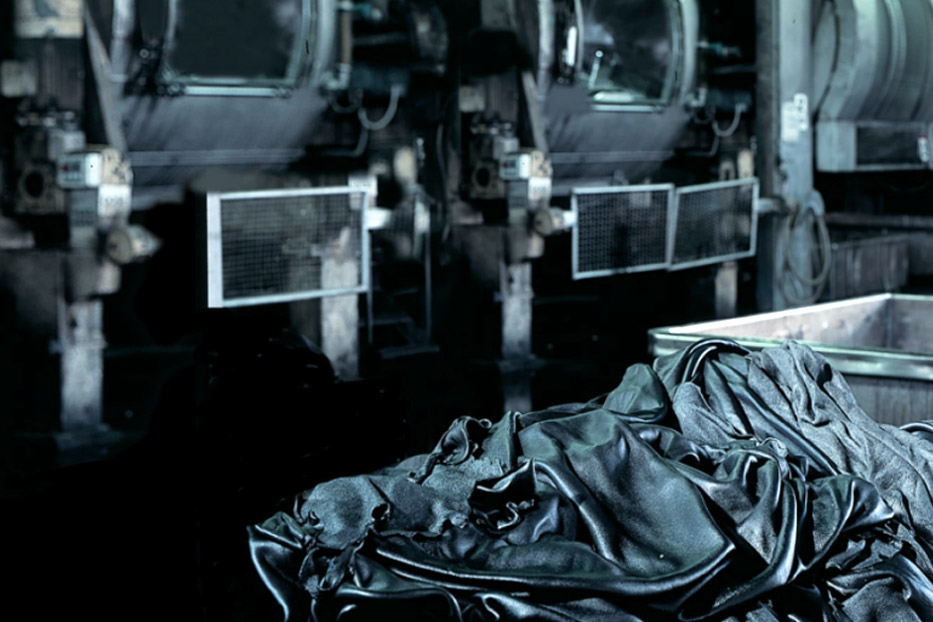

For the progress of the tanning process several big drums are used.

The dry-pressed skins are checked and selected according to their sorting. Almost scar and insect bite free skins are used for the purest leather applications.

The back side of the leather is rubbed to obtain an equal thickness.

The after tanning, colouring with aniline paint and after greasing process is done in big drums.

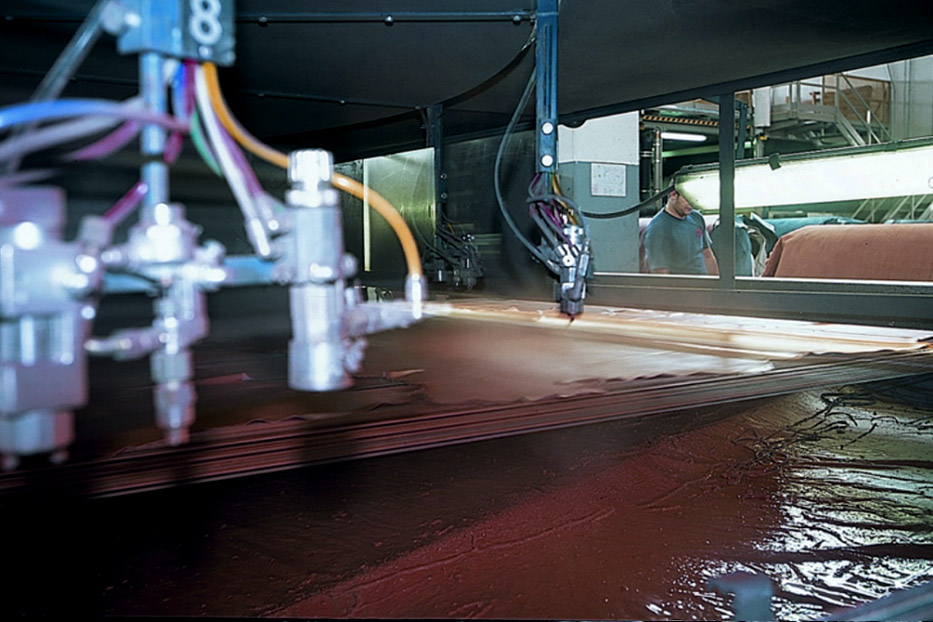

Automatic pistols apply a pigment layer on the skin surface.

Inspection and sorting of the finished leather.

Each product must comply with the required lab tests.

Nederlands

Nederlands Français

Français Deutsch

Deutsch